1. Low MOQ and Flexible Production Ability.

2. Quick delivery and standard industry exporting package.

3. Best service with 24 hour`s reply

4.Support payment with T/T,L/C , paypal, 100% LC ,etc.

5. OEM and ODM, welcome customers to visit our factory for better understanding;

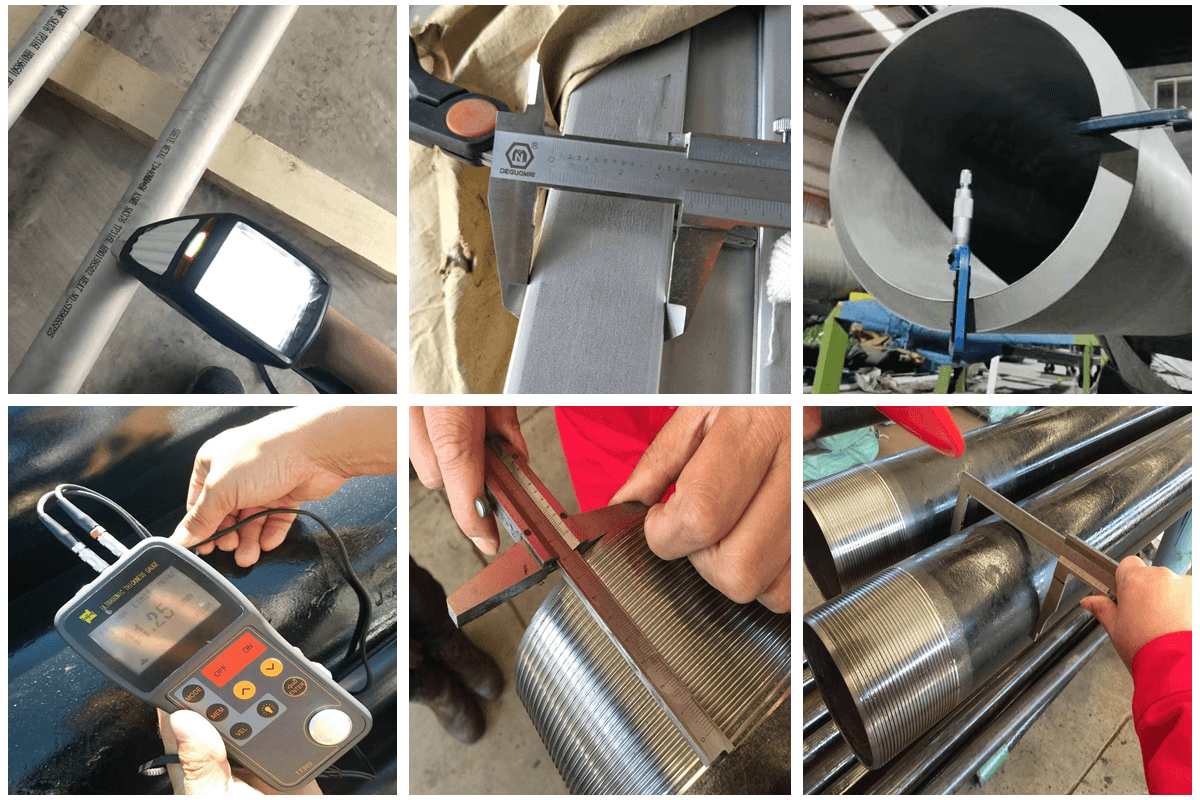

6. Approved by ISO9001, CE, third party inspection such as SGS BV is welcomed;

7. Our factory provide steel products with competitive price and reliable quality ;

8. Value friendship and trustworthy, devote to provide long-term service to our distinguished customers.

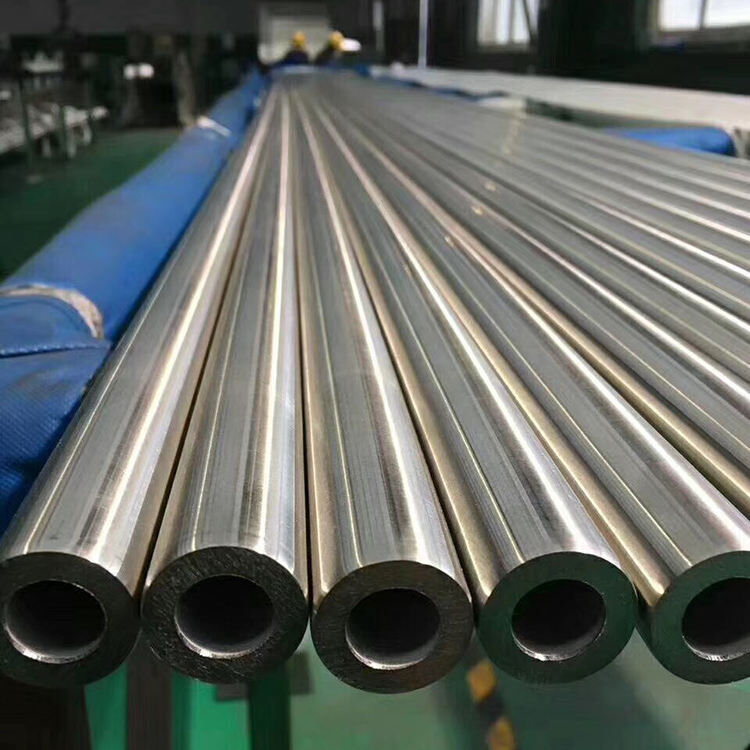

Product Description

Incoloy 800H Pipe Alloy 800H is chemically similar to alloy 800, differing from alloy 800 in that it has undergone a special solution treatment (grain size After ≥90μm/ASTM No.4), the tensile strength of alloy 800H above 600°C has been significantly improved. Below 600°C We recommend using alloy 800 for applications.

Incoloy 800HT Pipe Alloy 800HT is a solid-soluble high-strength austenitic nickel containing carbon, aluminum, titanium, silicon, manganese and increased (Al+Ti) content-Iron-chromium alloy with TiC precipitated precipitated phase after special solution treatment (grain size≥ 90 μm/ASTM No.4), Gives alloy 800HT the highest tensile strength above 700°C.

Characteristic of Incoloy 800H 800HT Pipe:

Incoloy 800H Pipe

1) Since the content of (Al+Ti) is not higher than 0.7%, alloy 800H has good tensile strength above 600°C, and still has good toughness when working below 700°C for a long time.

2) It has good resistance to corrosion resistance of reduction, oxidation and nitriding media and corrosion resistance to redox alternating changing media. High metallurgical stability in high-temperature long-term applications.

Incoloy 800HT Pipe

1) It has excellent yield strength above 700°C, and if the material is frequently used in an environment where the temperature is below 700°C or some materials are under 700°C for a long time, alloy 800H is recommended.

2) It has good resistance to reduction, oxidation, nitriding medium corrosion and redox alternating change media corrosion resistance, and has high metallurgical stability in high-temperature and long-term applications.

Get A Free Quote

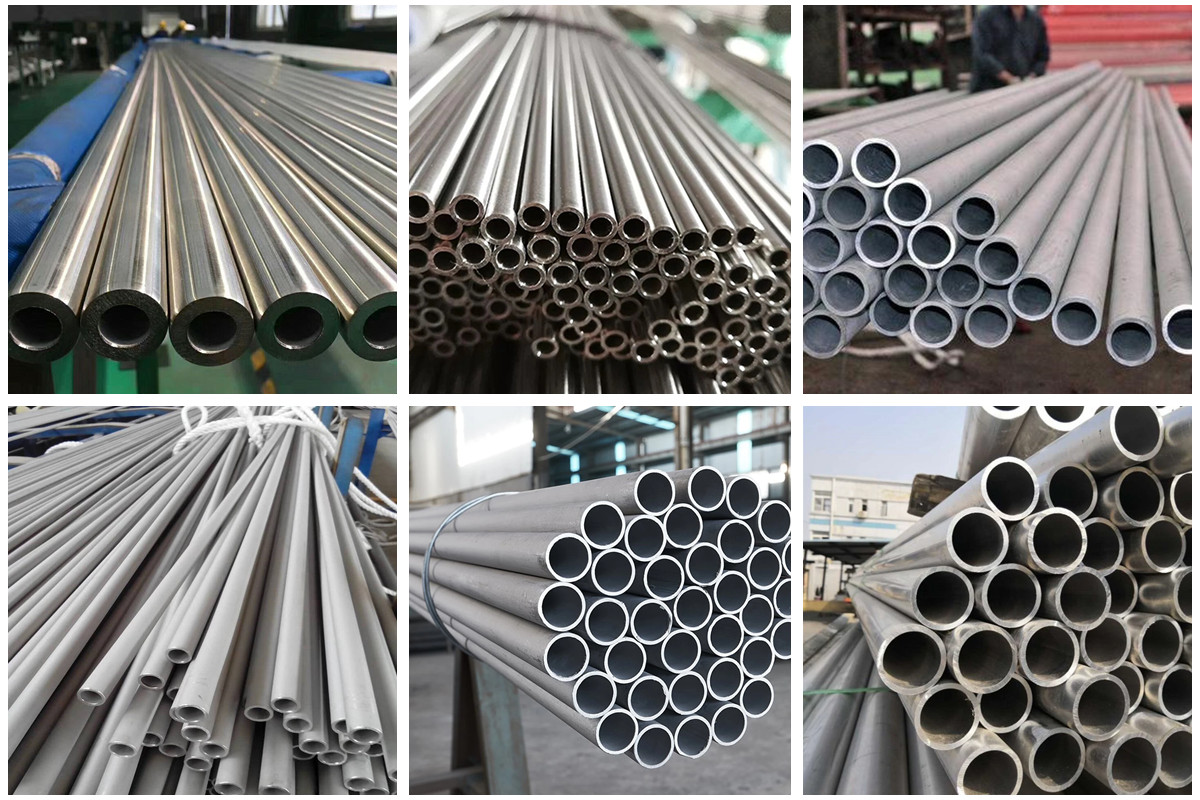

Related Products

Get A Free Quote