1. Low MOQ and Flexible Production Ability.

2. Quick delivery and standard industry exporting package.

3. Best service with 24 hour`s reply

4.Support payment with T/T,L/C , paypal, 100% LC ,etc.

5. OEM and ODM, welcome customers to visit our factory for better understanding;

6. Approved by ISO9001, CE, third party inspection such as SGS BV is welcomed;

7. Our factory provide steel products with competitive price and reliable quality ;

8. Value friendship and trustworthy, devote to provide long-term service to our distinguished customers.

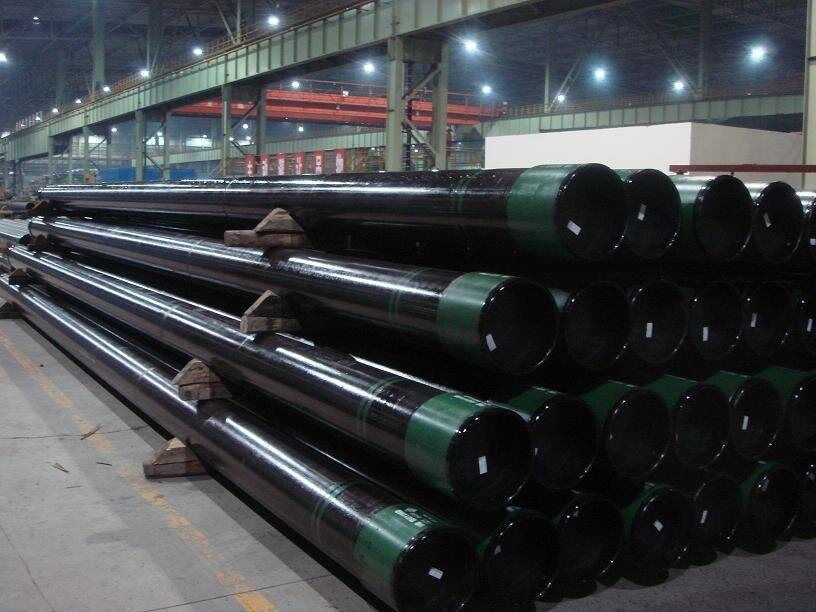

API 5CT L80 pipe OCTG is short for Oil Country Tubular Goods and refers to the pipes used in oil and gas extraction. The API 5CT standard covers the OCTG coupling, threading, and materials connections used in drilling operations. It includes instructions on dimensions, sizes, wall thicknesses, materials grades, tolerance limits, and performance requirements. The API 5CT is widely used in the oil and gas industry for both onshore and offshore drilling operations.

API 5CT L80 casing and tubing include grades L80-1, L80 9Cr (Cr 8%-10%), L80 13Cr (Cr 12%-14%), L80, minimum tensile strength 655 Mpa, yield strength 552 Mpa to 655 Mpa, it is a medium strength grade higher than J55/K55, and similar with N80 (YS 552 Mpa to 758 Mpa, TS 689 Mpa), L80 pipes has been used in oil well establishment, drilling and producinging oil and gas industries.

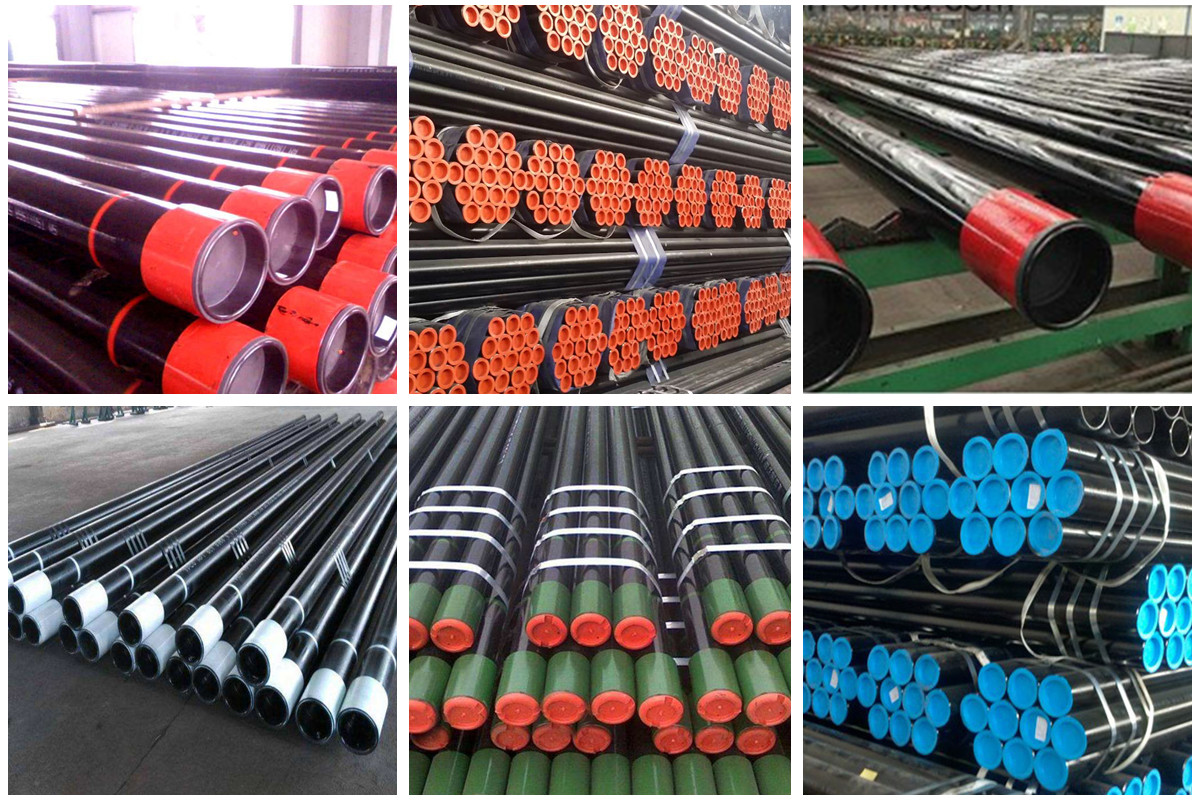

Connections of API 5CT L80 Pipe:

Common use connection BTC, buttress thread marked with BC

LC: Long round thread

SC: Short round thread

Premium connections like HYD, and other gas tight thread

Customized connection threads as per client requirement

Types of OCTG (Drill Pipe, Casing And Tubing):

OCTG stands for oil country tubular goods. It is a family of rolled metal products that are utilized in oil and gas drilling and production operations. The term OCTG encompasses a wide range of products, including drill pipe, casing, and tubing. These products are used to connect the wellhead to the downhole equipment, allowing oil and gas to be extracted from the ground. OCTG is a critical component of the oil and gas industry, and its products are essential for safe and efficient drilling operations.

Drill Pipe

Drill Pipe is a type of pipe that is used in oil and gas wells. It is made up of several different parts, including the kelly, the bit, the drill string, and the casing. The kelly is the part of the drill pipe that is attached to the rig, and it helps to rotate the drill string. The bit is the part of the drill pipe that drills into the rock, and it is usually made of steel or tungsten. The drill string is the part of the drill pipe that extends from the kelly to the bit, and it helps to provide support for the bit as it drills. The casing is the final part of the drill pipe, and it helps to protect the wellbore from collapse. All of these parts work together to help oil and gas wells function properly.

Casing Pipe

Casing and tubing are both used in the process of drilling for petroleum. The casing is placed before drilling begins and surrounds the wellbore. Its purpose is to protect the soil layers and groundwater from contamination by drilling mud and/or frac fluids. Additionally, the casing stabilizes the wellbore. Drilling and casing operations alternate – the drill string is removed at predetermined intervals and the wellbore is lined and cemented with casing.

Tubing

Tubing is used to carry petroleum from the well’s depths to the surface. This is the third phase of the wellbore process. Oil and gas occasionally self-elevate to the surface; however, pumps are typically required to bring the fluids to the surface. Besides the 4 1/2-inch diameter, tubing is normally smaller in diameter than the casing.

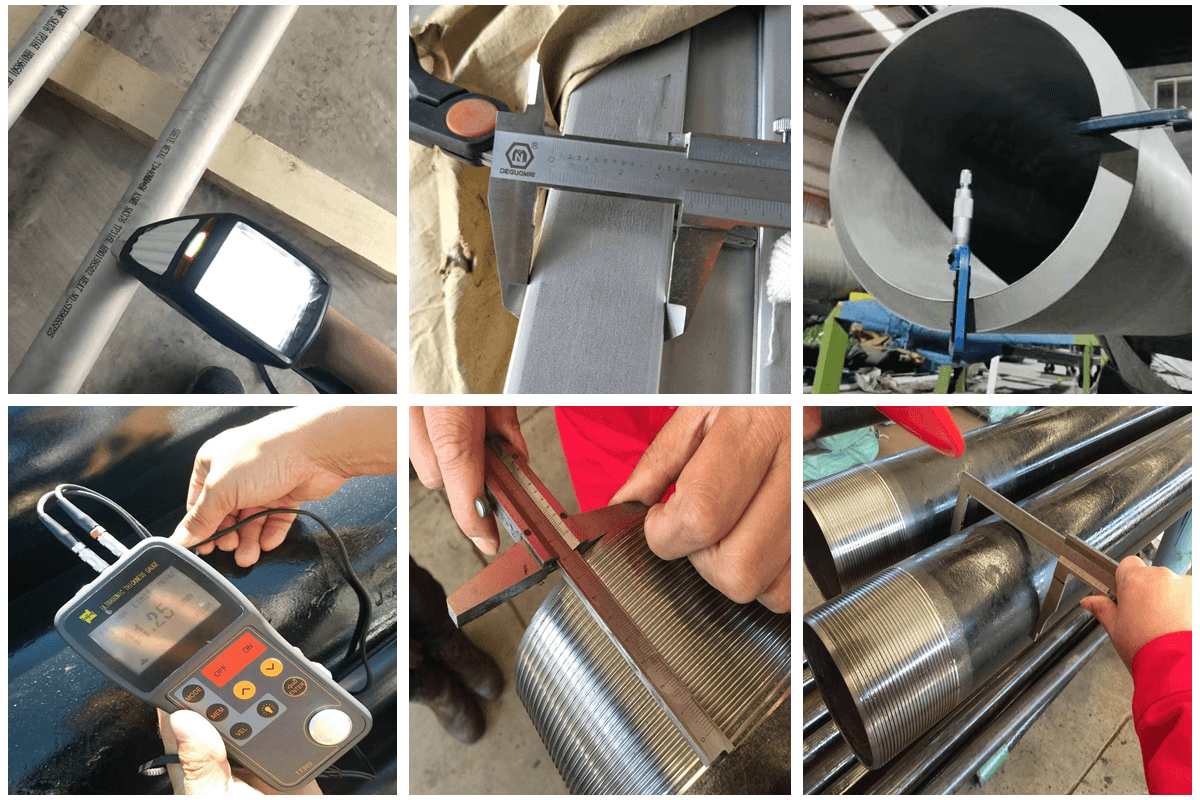

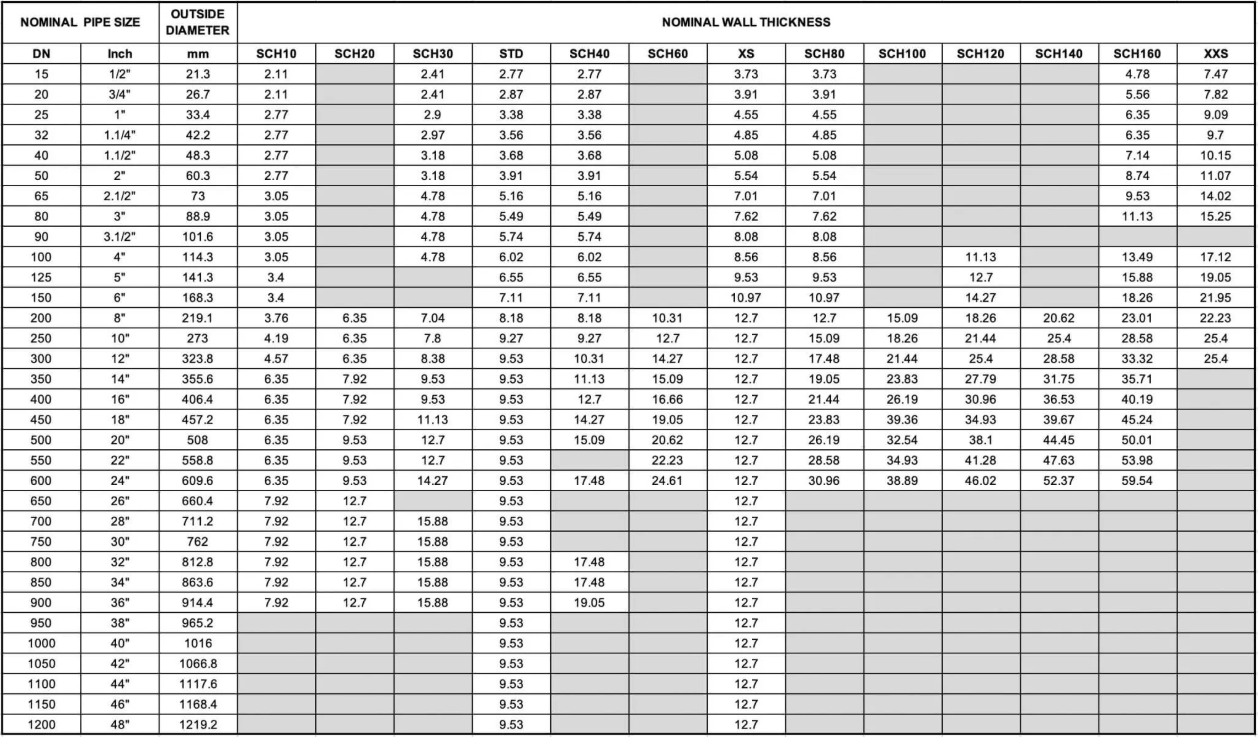

Dimensions And Wall Thicknesses of OCTG Pipe:

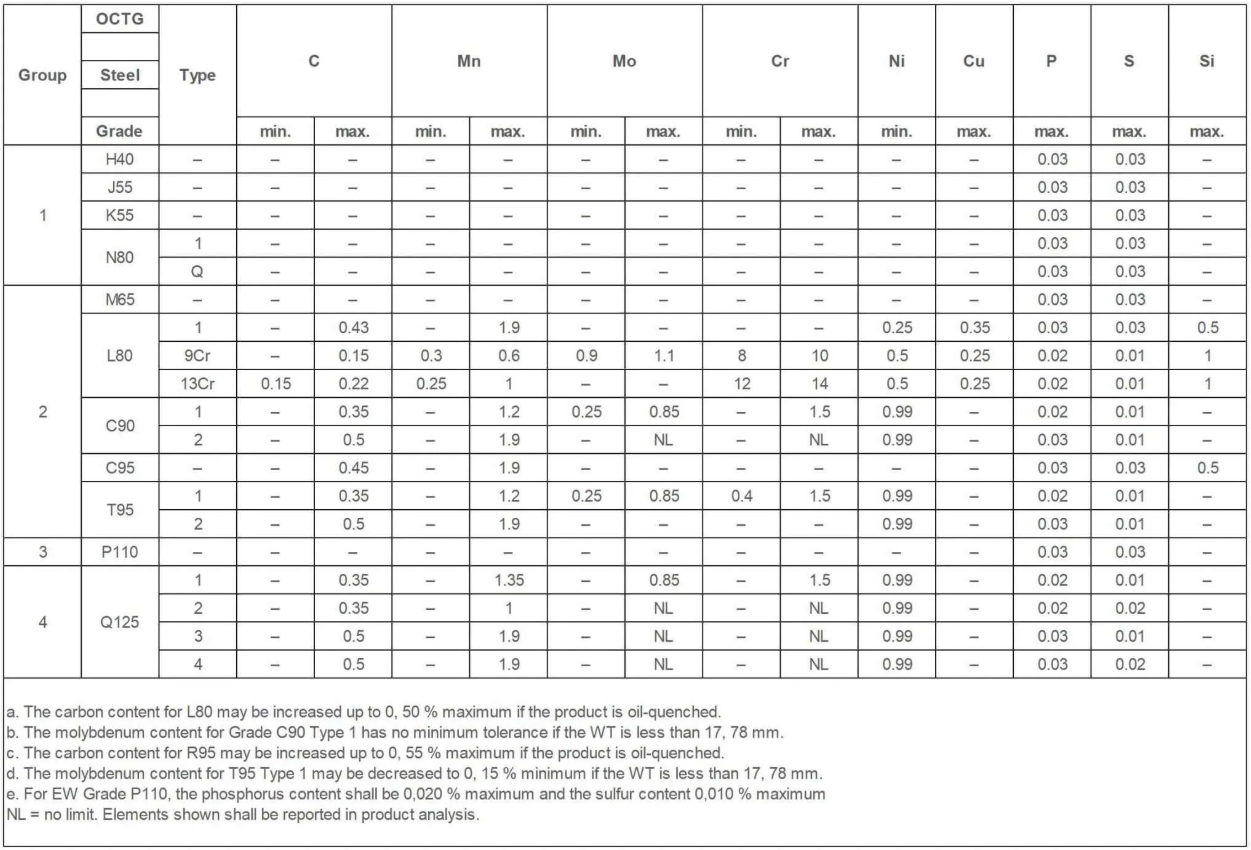

OCTG Pipe(Tubing and Casing) Chemical Component:

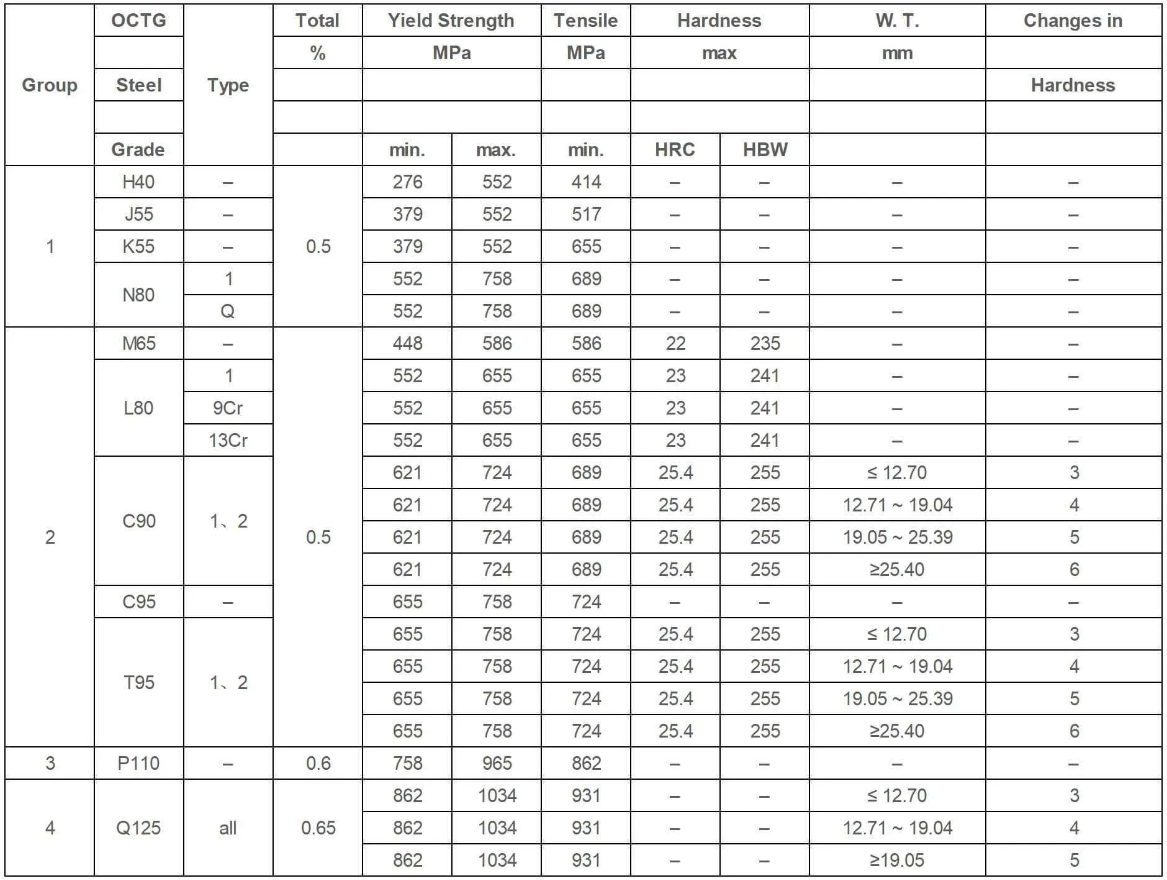

Mechanical Properties Of OCTG Pipe(Tubing and Casing):

Get A Free Quote

Related Products

Get A Free Quote