1. Low MOQ and Flexible Production Ability.

2. Quick delivery and standard industry exporting package.

3. Best service with 24 hour`s reply

4.Support payment with T/T,L/C , paypal, 100% LC ,etc.

5. OEM and ODM, welcome customers to visit our factory for better understanding;

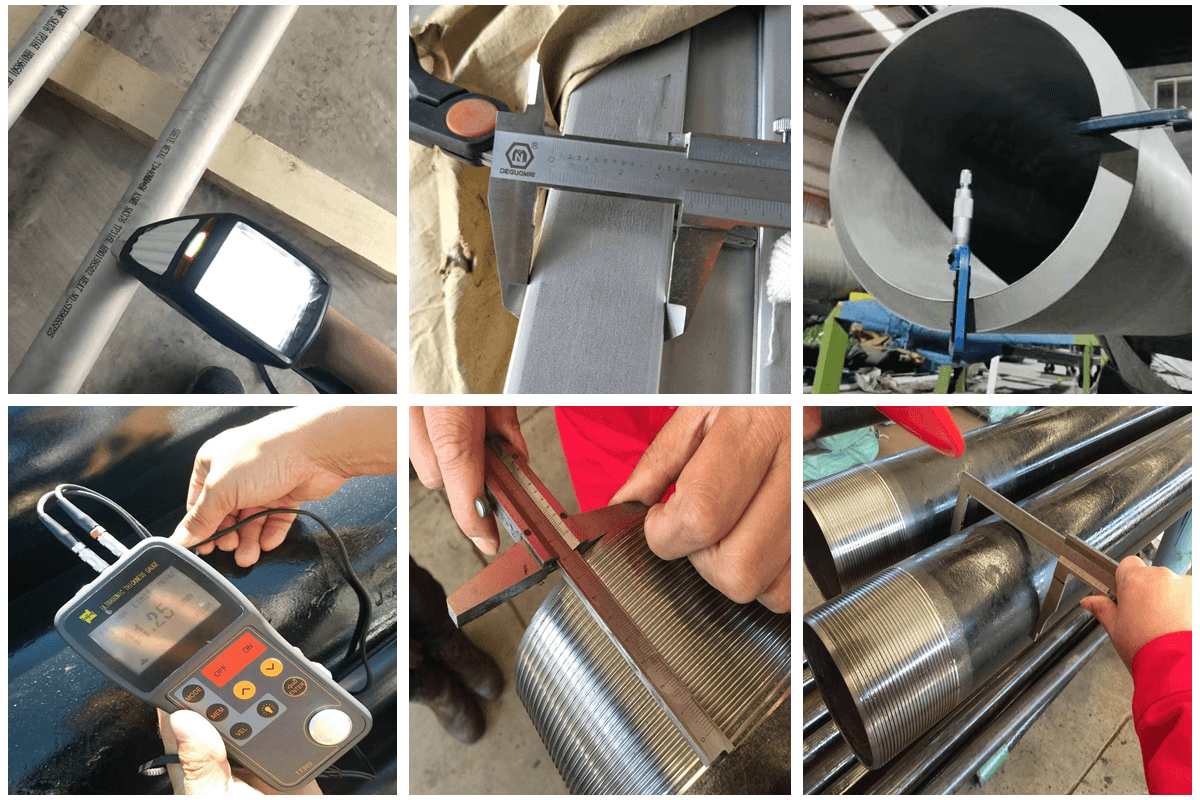

6. Approved by ISO9001, CE, third party inspection such as SGS BV is welcomed;

7. Our factory provide steel products with competitive price and reliable quality ;

8. Value friendship and trustworthy, devote to provide long-term service to our distinguished customers.

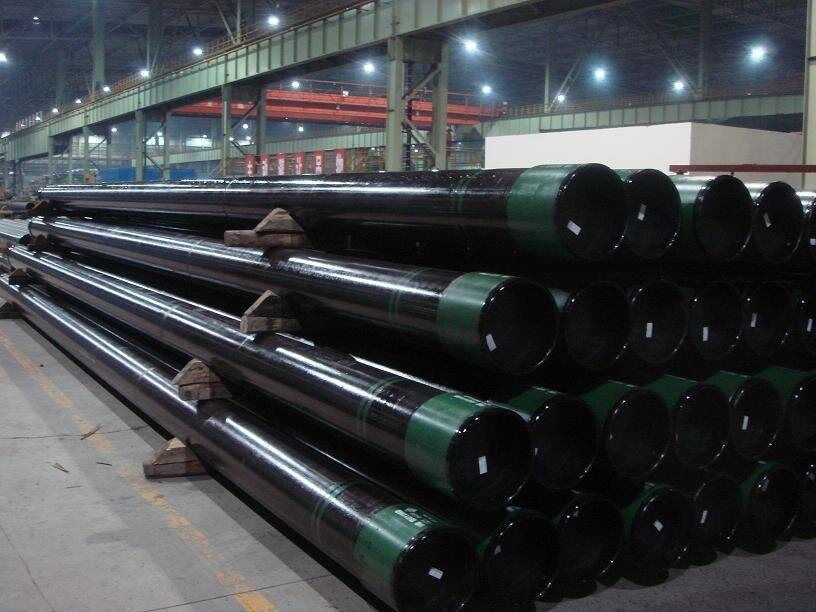

API 5L X46 line pipe API 5L X46 line pipe is a petroleum-transporting pipeline used onshore and offshore. The steel line pipe is widely used in the petroleum industry to transport oil and natural gas from the ground to refineries and other processing facilities. It is also used in the construction industry to transport water and other fluids. The API 5L X46 line pipe is manufactured to meet the requirements of the American Petroleum Institute (API) standard. The line pipe is available in different grades, ranging from Grade B to X80, to accommodate different types of applications. The most common grade used in the petroleum industry is Grade B, X42, X46, X52, and X56.

What Is The Difference Between Seamless API 5L Line Pipe And Welded API 5L Line Pipe?

Line pipes are appropriate for a range of standards. According to consumer needs, production meets the line pipe of various standards. We are usually made according to metallurgical requirements that were developed by the American Petroleum Institute (API). API 5L Specifications cover seamless and welded pipes suitable for use in conveying H2O, fuel, and other liquefied media. It is used in line pipe production worldwide. Pipelines are made in a wide variety, varying in dimensions from 2 to 24 inches. Depending on the customer’s needs, pipeline manufacturers can produce either seamless or welded pipes. The main difference between the two is that the latter has a seam that is created during the manufacturing process, while seamless pipes do not have this seam. Both types of pipes have many uses, and which one is right for a particular project depends on and is limited to several factors such as cost, application, and transportation. Seamless pipes are typically more expensive, but they have superior strength and durability which is preferable for your project. Though the other type is less expensive but may be more prone to leaking. It is also important to note that when choosing, make sure that whatever material you are going to use, is accredited by ASTM. All of these must be considered in accomplishing a CSA. Therefore, it is important to search for consulting services where a trained professional can help you determine which types of pipes are best for your needs.

What Is The Difference Between API 5L Line Pipe PSL-1 And PSL-2?

In the oil and gas industry, the API(American Petroleum Institute) designates different levels of steel pipe. The two most common levels are PSL1 and PSL2. PSL stands for Production Survey Level. These levels are based on the properties of the steel, as well as how often it undergoes testing.

PSL-1 is the lower grade, and it is generally used for less critical applications. The chemical and mechanical requirements are not as strict, and the test frequency is lower.

PSL-2 is the higher grade, and it is typically used for more critical applications. The chemical and mechanical requirements are stricter, and the test frequency is higher.

So, in summary, the main difference between PSL-1 and PSL-2 levels is that PSL-2 has stricter requirements and a higher test frequency. This means that it is a higher quality level of steel pipe.

Types of Line Pipe:

Pipelines can be categorized into different types. The following pipelines are classified according to the type of fluids and items transported. It is important to read the following for an understanding of each type.

- Water and Drain Line Pipe

This type is used to carry H2O from one location to another. They are typically made of metal or plastic, and they are usually buried underground. These are typically coated with a material that helps to prevent rusting. In addition, such pipelines may be equipped with fittings that help to connect to other types of pipes or fixtures. They are an essential part of any plumbing system, and they are typically used in residential, commercial, and industrial applications.

- Oil Line Pipe

This type is defined as having the advantage to be used to carry petroleum products such as crude oil and natural gas. They are typically made of steel or iron, which can be susceptible to rusting. To protect the pipes from rusting, a coating is often applied. This coating can be made of various materials, including plastic and resin. Once the petroleum products have been transported through the pipelines, they can then be refined into useful products such as gasoline and diesel fuel.

- Gas Line Pipe

The specification of types of pipelines is that it is used to carry and transport natural gas. It is generally made of steel, which is a strong and durable material. However, over time, steel can start to corrode and weaken. To protect the pipelines from rust, it is often coated with a layer of plastic or other material. Such pipelines are typically buried underground, but they can also be installed above ground. The pipelines must be properly maintained to ensure that it does not leak or burst, which could pose a serious safety hazard.

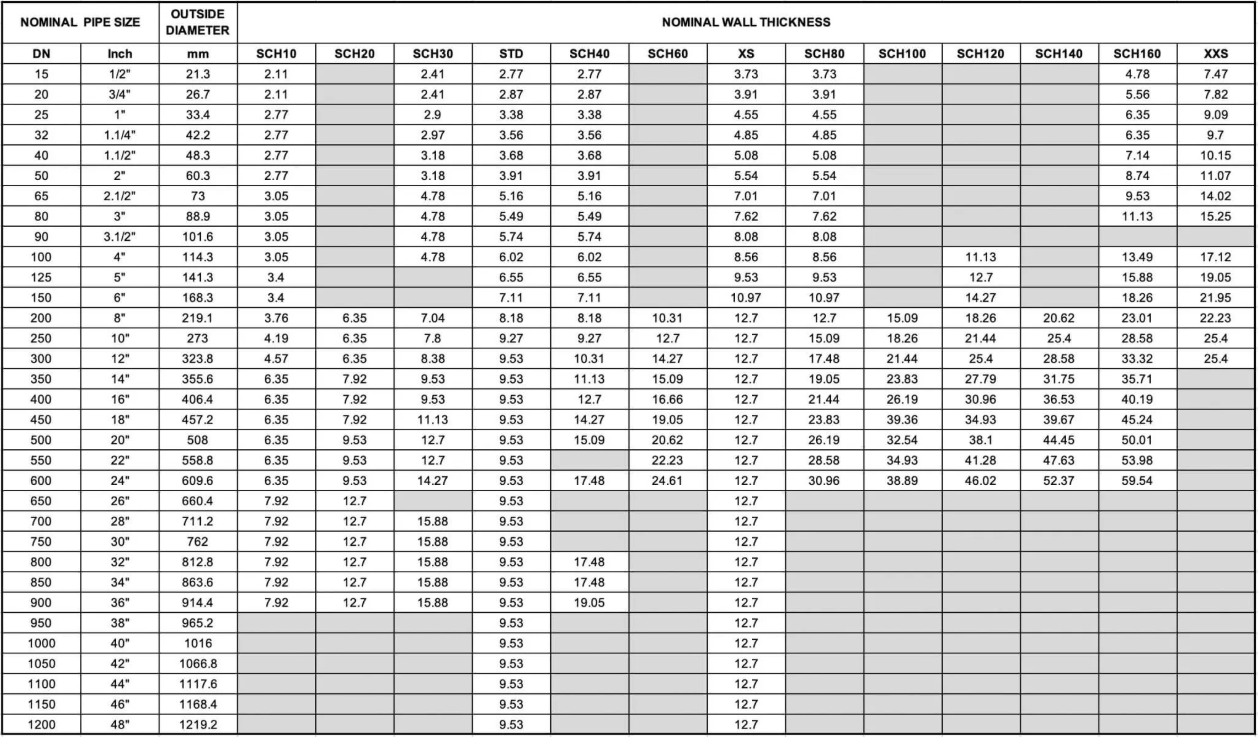

Dimensions And Wall Thicknesses of Line Pipe:

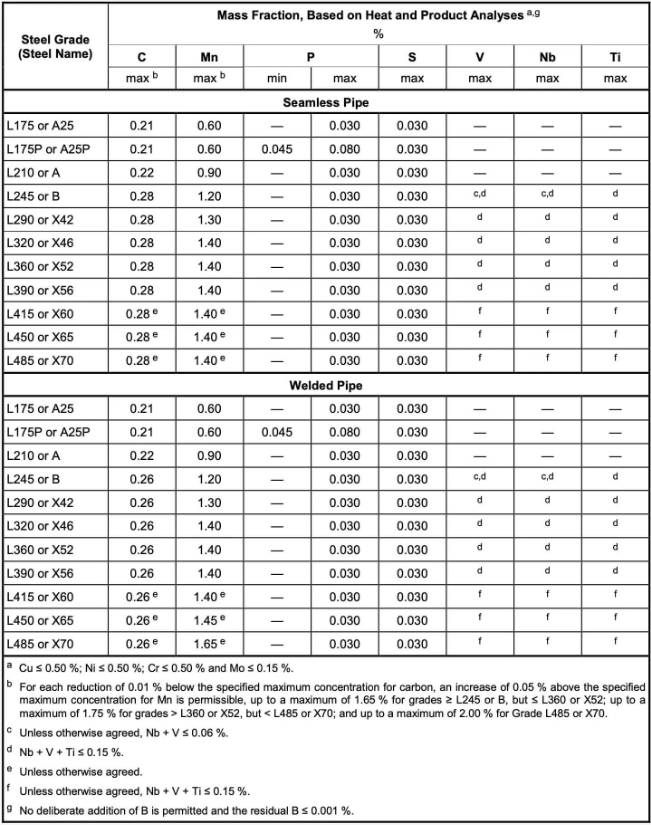

API 5L Line Pipe Chemical Component:

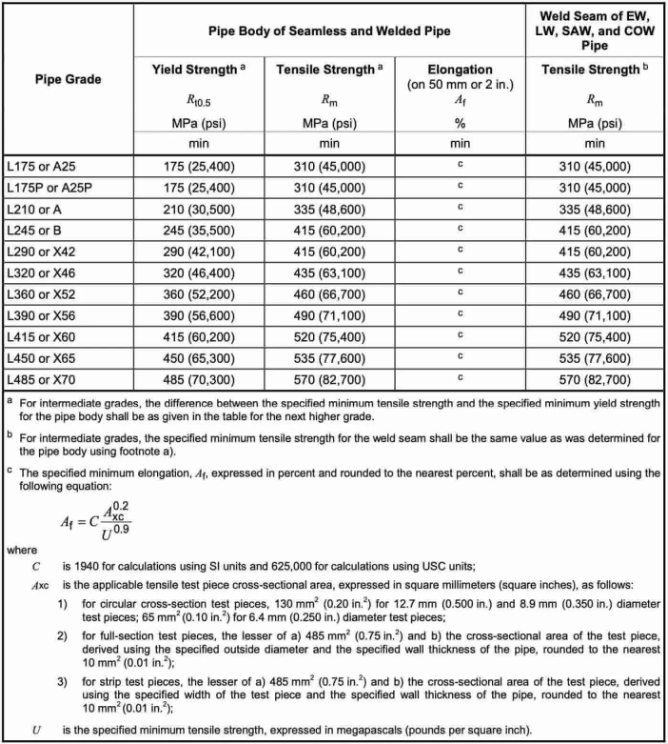

Mechanical Properties Of API 5L Line Pipe:

Get A Free Quote

Related Products

Get A Free Quote