1. Low MOQ and Flexible Production Ability.

2. Quick delivery and standard industry exporting package.

3. Best service with 24 hour`s reply

4.Support payment with T/T,L/C , paypal, 100% LC ,etc.

5. OEM and ODM, welcome customers to visit our factory for better understanding;

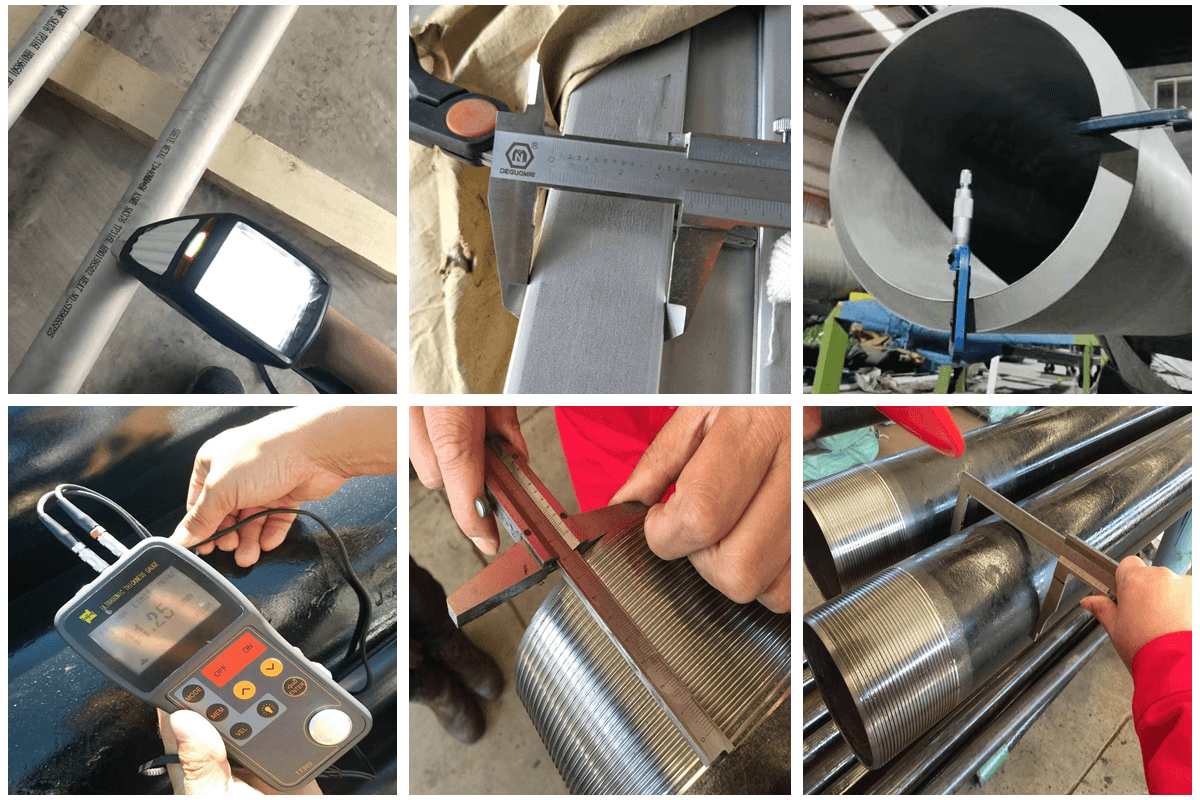

6. Approved by ISO9001, CE, third party inspection such as SGS BV is welcomed;

7. Our factory provide steel products with competitive price and reliable quality ;

8. Value friendship and trustworthy, devote to provide long-term service to our distinguished customers.

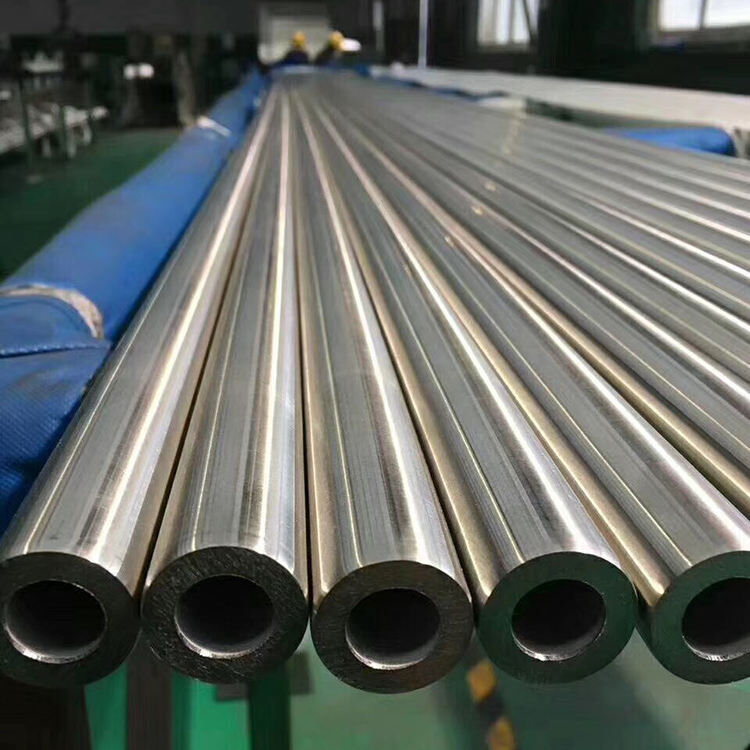

Product Description

Comparison of Hastelloy Pipe:

1) "G" alloy The corrosion resistance of alloy G-3 exceeds that of alloys 400, 600, 825 in many uses. This alloy is particularly resistant to the corrosion of sulfuric acid and impure phosphoric acid, can withstand the erosion of two environmental conditions of reduction and oxidation, alloy G-30 welding performance is better, and the corrosion resistance ability is comprehensively improved, especially the corrosion resistance of the heat affected zone of the weld.

2) "C" alloy For the chemical industry in special corrosive environments, alloy C-276 is considered to be an excellent alloy, with very special resistance to various acids, acid salts and other aggressive substances encountered in the chemical treatment process.

Alloy C-276 is suitable for harsh environments such as moisture-filled chlorides and hypochlorite. Because alloy C-276 contains molybdenum, this alloy is more resistant to chloride-induced pitting and crevice corrosion.

3) "B" alloy alloy B-2 has outstanding resistance to sulfuric, phosphoric and hydrochloric acids under reducing conditions. It is particularly suitable for equipment that processes hydrochloric acid at any concentration and all the way to boiling point temperature.

Get A Free Quote

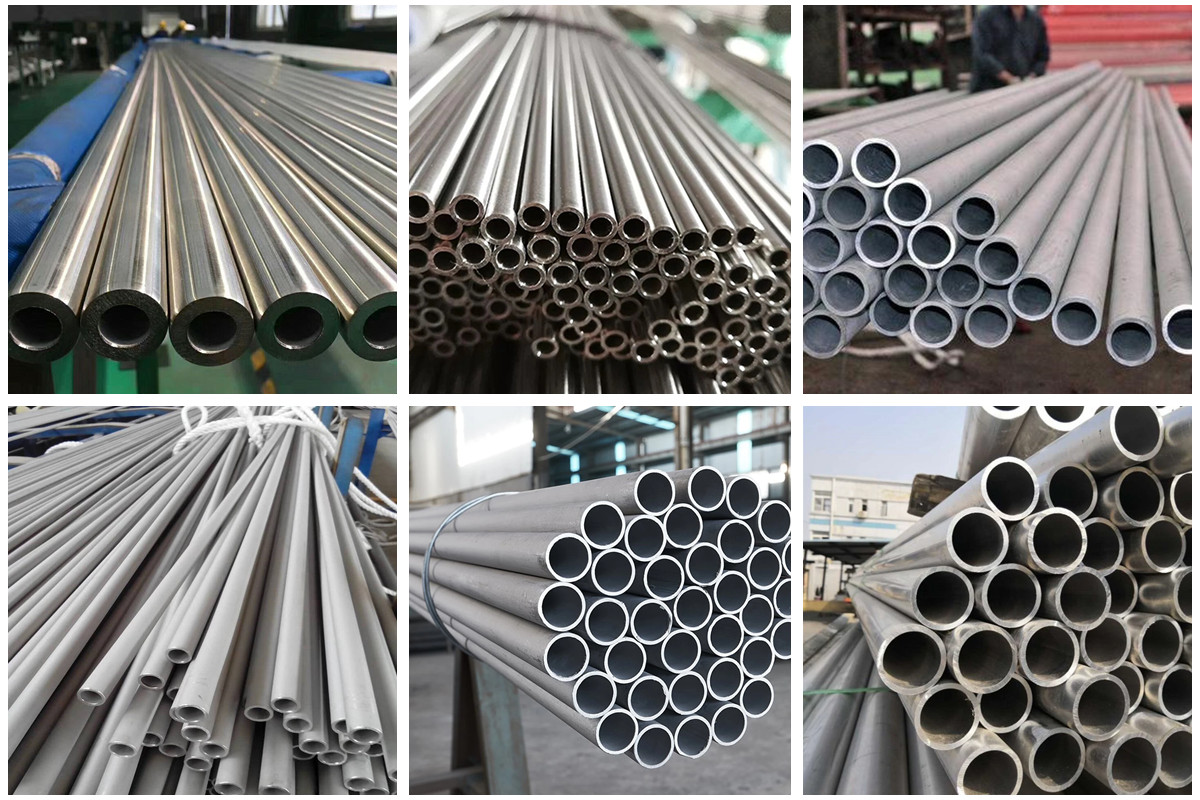

Related Products

Get A Free Quote